Why a Flat-bottomed Pram for Fly-fishing?

|

This post was updated on .

For fly-fishing small lakes, a rowboat is one of many choices, as are float tubes, pontoon boats, canoes, kayaks, pirogues, or jon boats. It mainly depends on what you are familiar with, whether you prefer to build than buy, and how you intend to transport and store your craft. If a 'rowboat', then choices are skiffs, punts, prams, garveys, sharpies, etc., and the hull configs are 'flat', 'round', 'vee', or 'tunnel'. But what offers easy enough construction and the most initial stability (for standing to cast) is a flat-bottom punt or pram.

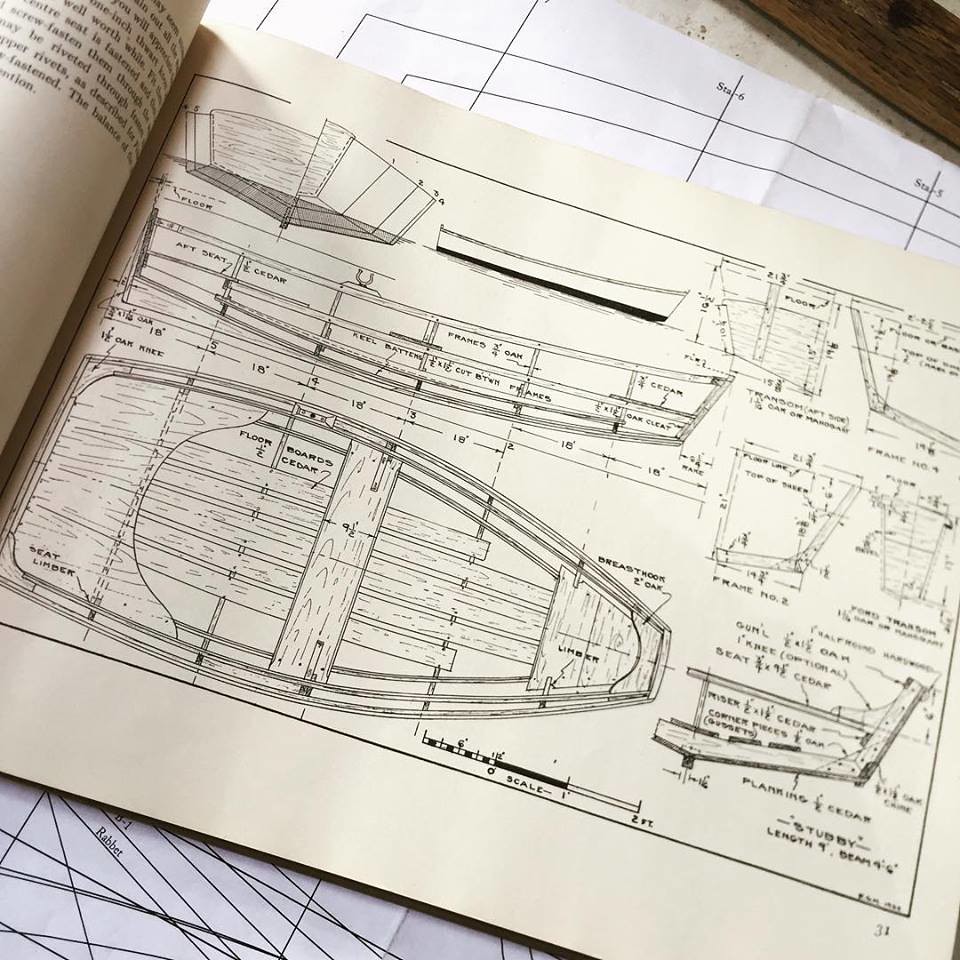

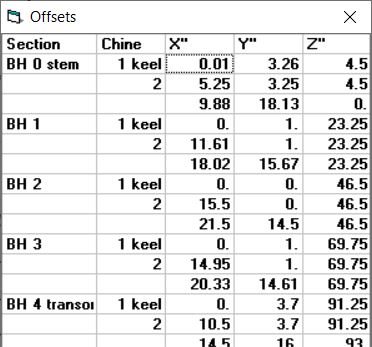

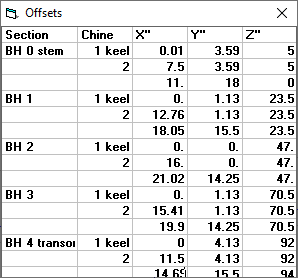

I've built a lot of them in lengths from 8' to 10'. Boats that small are single-user boats, not so much because they're small, but because that's the nature of fly-fishing. It just isn't safe or practical to have two people in the same boat throwing 60' of line over their shoulders and past each other's ears and eyes. Somebody is going to get snagged, sooner or later, never mind having constantly to be aware of how the other person is moving about in the boat, so you both don't end up in the drink from someone leaning too far over the side when netting a fish. (Nah, never happened to me. ROTFL). Of the prams I've built, plenty were design failures that I promptly chainsawed. But there've been a couple of success as well, two of which I'd like to share in enough detail that anyone could build them (or similar), and I do emphasize ''or similar", because there isn't only right way way to do any of this boat-designing/boat-building stuff, only best guesses as to what might work well enough to repeat on the next boat. What I'm calling my Britton 8 and Britton 9 aren't plans to build a specific boat, but a cluster of design objectives and construction methods that combines the look and methods of Ed Monk's Stubby and Steve Redmond's Tetra to produce a light-weight, low-cost, car-toppable, beach-launchable, single-user pram meant for fly-fishing protected water. In general, my prams have these characteristics: a flat bottom, a single chine, doubled skegs, shallow rocker, radial lapped framing, fillet weld chine and seams, oiled interior/varnished exterior, scuppered gunnel, transom knees, no corner knees, crowned transoms with handholds, prominent seat riser, single removable thwart, oarlock blocks, and a mid-plank rubbing strip. I'm sure there are other details I'm overlooking. But those are the ones that make my boats to be "my boats", and no one else's.   Years ago, 'one-sheet rowboats' were all the rage, and they still intrigue me. But they really are too tiny to be anything but a kid's boat, and a pretty small kid at that. The problem with 'one-sheeters' isn't their necessarily short length, but the lack of freeboard that positions the oarlocks --even when raised on blocks-- too low for the boat to be rowed comfortably by even a smallish adult. But if the boat is cut from 1-1/2 sheets, then adequate midship depth can be achieved, such as for my own 5'6". (A taller rower would need even more midship depth, which can be achieved by using 2 sheets.) So, these become the design questions: How tall is the rower? How much does he/she weigh? How much "roominess" is desired? How much lateral initial stability is needed? How important is it to minimize costs, labor, or materials? The cheapest path to building a Britton 8 is to cut the boat from 1-1/2 sheets of BS 6566 --hence, buy 3 sheets and talk a friend into building a second boat at the same time-- and to frame with WRC. This produces a very decent hull that I can verify by having built two and fishing them hard for a week of "sea trails" before donating both to a kid's summer camp, where other users' reports were also favorable. However, the downside of that path is the boat needs to be put together with epoxy fillets, and if this will be your first boat, then other fastening methods will be easier and cheaper for you. (More later on that.) The chief diff between 6566 and 1088 is the thickness of the face plies --1mm vs 1.3mm-- not the glue used or the lack of voids in either. Likely, the species will be Merenti, which pairs well Black Walnut if the boat is to be finished bright. However, walnut runs about $8/bdft vs $0.75/bdft for construction-grade WRC, and is a whole lot heavier, though less subject to impact damage. So, from the getgo, you've gotta decide whether you want to plank with Okume vs Merenti and what woods you want to frame with. If you go with Okume --which pairs well with WRC, if the boat is to be finished bright-- then you've got a further choice: 4mm vs 6mm? Also, if you go with Okume, you pick up another 2-7/16" of length, because metric ply is 48" x 98-7/16" vs standard marine ply's 48" x 96". So, again, "chef's choice". It all depends on how tight your budget is, how durable you need the boat to be, how burdensome, how light, and how concerned you are that the boat look like "floating furniture". If you go with the combo of 4mm Okume and WRC, you're talking a sub-40 pound hull. If 1/4" ply and walnut framing, then a 50-pound hull, which is still light and offers no worse (nor better) hull performance, which is determined by the boat's lines, not its detailing. Here's yet another "chef's choice": Do you want to build plank-on-frame, stitch-and-glue, position-and fillet, or fit-and-goop? Do you need to avoid exposure to epoxy? Are you willing to use an external chine? How many clamps do you have? Do you have access to a thickness planer? Given that I've got a Britton 9 I'm happy with and a light-weight Britton 8 on the building frames -- but not a currently completed one, for having given the last one away--, I'm going to build the boat to suit my preferences, rather than what might be guessed are the needs of other builders. My inclination at this point is to borrow a term from the motorcycle crowd and to build a 1-1/2 sheet "dresser". That means planking with 1/4", 1088 Merenti ($50/sheet form Shurway), framing with Black Walnut, and --of course-- finishing bright. Below is the table of offsets, which is all you need to build the boat. But I'll be walking you through the construction steps as they happen and pointing out the changes you should probably make to fit your own height, weight, and construction skills.  |

|

This post was updated on .

For that table of offsets to make sense --and for you to be able to make changes and then produce cutting patterns--, you need to install Gregg Carlson's HULLS program, which is the easiest to use of the half dozen, freeware, marine CAD programs out there. The downside of HULLS is that it's legacy software that Win 10 won't run unless you tell it to run using an earlier version of Windows. If you have trouble, find a YouTube video that will walk you through the process. But get HULLS installed, or else you won't be able to build a boat that matches your height and weight, which isn't likely to be my 5'6" and 120 pounds.

https://carlsondesign.com/projects/hull-designer/ Gavin Atkin has written a tutorial for HULLS, but it's mostly a confusing waste of time. The way to learn HULLS is to open it up and to start clicking on things. Once you've gotten used to dragging lines and entering numbers, then find a library example that's close to the boat you want to build. Make your changes to its dimension, clear old patterns, save the file with a new name, and then open the nesting patterns to see how your boat lays out on ply. If all looks well, then loft enough of the boat to pick up the bow and stern angles and make drawing for the transoms. That summary paragraph won't make sense to you unless you've learned how to use HULLS and have already built a boat or two. So I'm going to have to slow down and walk you through each step in tedious detail. But the first step --some how, some way-- is to get HULLS installed, as well as this freeware grafting program. https://www.padowan.dk/download/ |

|

This post was updated on .

As always, "Life is what happens when you were planning to do something else."

A friend wants a boat for fly-fishing and is absolutely certain he wants 'high initial stability' (for standing to cast). A 'light-weight' hull (for easier car-topping) is also high on his list of priorities. Of less definiteness is the possibility of hanging a small, 27-pound thrust electric motor off of the transom (that adds the design complication of an old-style, 60-pound battery). 'Light-weight hulls', such as might be accomplished by planking with 4mm ply and framing with WRC, just don't pair with 60-pound batteries, given that the friend tips the scales at 210. Clearly, he needs two boats, not one boat that tries to accomplish contradictory goals. He needs a smallish, single-user, light-weight pram and a bigger, longer, more hydro-dynamically efficient hull, such as a wherry, for when the distances to be covered make using a motor a sensible choice and it might be desirable to accommodate a second person. There's no need for me to draw a wherry (or similar), not when plans for them are widely available, and he "volunteered" to do the searching. Plans for prams are also widely available, but they don't focus on the single task of being a low-cost, light-weight, car-toppable, beach-launchable means for a user of a specific weight to stand to cast on protected water. Therefore, the pram has to be drawn. It will be a bigger, more burdensome boat than what I'd need for myself. But a pram is a pram, and I've drawn and built a lot of them. |

|

This post was updated on .

It's been a while since I posted, and my building plans have changed as well. Rather than do a sheet-and-half "dresser", what I've got on my building frame right now is the start of 8'10", flat-bottomed, single-chine pram to be planked with 4mm Okume and planked with WRC. The bottom is roughed out (over-sized, because I'll be using an external chine). The bow and transom have been built, though the bevels haven't yet been cut. The sides have been cut and butt spliced.

Why did I make the design decisions I did? E.g., why an external chine rather than a more hydro-dynamically efficient one? Think about the purpose of the boat, which is fly-fishing protected water. How much of one's time on the water will be spent rowing to get somewhere efficiently and quickly and how much time will be spent positioning the boat for the next cast? If one's goal is to travel long distances as easily as possible, then you're going to be choosing a wherry, whitehall, or guide boat, not a pram, not that even a very short and moderately beamy pram that puts at least 81" on the waterline can't offer a t will offer a very respectable theoretical hull speed of 4 MPH. |

|

Well, I chain-sawed another one, because it just wasn't working out. Fortunately, I'll probably be able to re-purpose the sides and bottom. So, instead of 8'10", I'll be building a 93-94" incher, or what can be cut from standard sheets of ply without scarfing planks.

|

|

It's been forever since I last posted. So here's an update.

After a year of talking back and forth with my prospective design "client" (a buddy who thought he wanted a light-weight boat for fly-fishing), I've finally convinced him to use a boat and trailer he already has, namely, a Salt Bay, which makes a decent single. At this year's Family Boat Build, someone else approached me about drawing him a boat. But since he failed to get back to me in a timely manner, I now have no one to please but myself. I found this year's FBB hugely inspiring. I liked its compactness and it's quietness. No crowds of people asking the same questions. No obnoxious band. Just seven families working on their boats without needing much direction, which gave me a chance to think about what features I like to have in my own boats. |

|

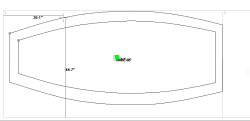

Two days of drawing boats has gotten me to where I always end up, a (nominal) 8' foot, flat-bottomed pram, for such boats being what I like to draw and build. (Actual: 94" x 42", x 14.5".)

If I plank with 1/4" Merenti and frame with walnut, I'm guessing a tolerable hull weight of 50 pounds. Theoretical hull speed at 200 pounds displacement will be 4 MPH, or plenty fast enough for a fly-casting platform. Cute boat, right? My intention is to build it Salt Bay-style, i.e., jigless with an external chine, but use Tite Bond III and ring-neck nails rather than screws and PL Prem. Lumber costs are up, as everyone knows. But my bet is that finished costs (including varnish and oars) will be under $25 per foot.  |

|

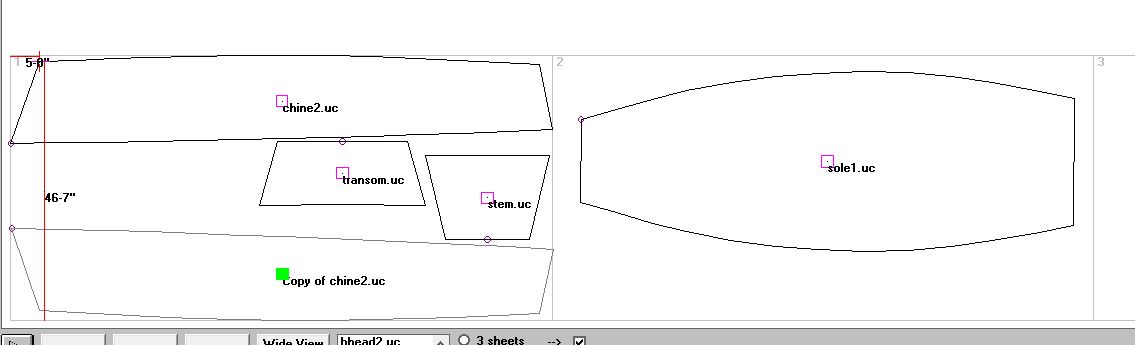

Below is the table of offsets and the cutting patterns. (This is NOT an efficient layout, because two slightly smaller boats could be cut from just 3 sheets, which I've done before.)

The sides fit lengthwise on a 4' x 8' sheet. There's enough material to crown the bow and stern transoms. The bottom is to the inside of planking, but must be cut oversize due to using an external chine. The boat will need to be lofted to pick up the angles needed to build the bow and stern transoms. But that's no biggie.   |

Re: Why a Flat-bottomed Pram for Fly-fishing?

|

Great work!

|

«

Return to General discussion

|

1 view|%1 views

| Free forum by Nabble | Edit this page |